(Vancouver BC) – Mark Jarvis, CEO of Giga Metals Corp. (TSX.V – GIGA) today announced analytical results from 15 holes drilled in 2021 on the Company’s Turnagain Nickel/Cobalt Project.

The 2021 work program included:

- Nine NQ resource infill holes totaling 4,214 metres within the Horsetrail and Northwest zones of the Turnagain deposit.

- Six HQ geotechnical holes totaling 2,082 metres sited on the margins of Horsetrail and Northwest zones of the Turnagain deposit to support pit engineering design.

- Seismic refraction survey in Flat Creek Valley in support of tailings management engineering design.

“The infill drilling is focussed on later years in the mine life, at the edges of the pit design in our 2021 PEA,” said Mr. Jarvis. “The drilling was designed to allow for conversion of resources from the Inferred to the Indicated category, and we have not seen any surprises. The geotechnical holes within the proposed ultimate pit provided valuable geotechnical information and, where ultramafic rocks were intersected, are expected to move some Indicated resources to the Measured category. Additionally, the Company now has acquired valuable geotechnical and hydrogeological data with which to advance the project engineering.”

Technical Information

This release provides analytical results from 15 holes from the 2021 drill program and the Turnagain Project. The drill program, conducted with two skid-mounted drill rigs, commenced on June 30, 2021 and ended October 12, 2021.

Resource Infill Drilling Program

The infill drilling program was conducted with one skid-mounted drill rig in the Horsetrail and Northwest zones in areas of Inferred resources. Drill core samples were one-half NQ core.

Table 1: Drill intercepts from the resource infill program1:

| Hole | Zone | From | To | Interval | Ni | Co | Pd | Pt |

| (m) | (m) | (m) | (%) | (%) | (ppb) | (ppb) | ||

| DDH21-307 | HT | 84 | 358.75 (EOH) | 354.75 | 0.221 | 0.014 | 26 | 35 |

| Including | 20 | 98 | 78 | 0.232 | 0.015 | 54 | 90 | |

| DDH21-308 | HT | 6.95 | 477.62 (EOH) | 470.67 | 0.214 | 0.013 | 23 | 24 |

| Including | 6.95 | 54 | 47.05 | 0.25 | 0.014 | 18 | 24 | |

| and | 408 | 440 | 36 | 0.252 | 0.013 | 28 | 26 | |

| DDH21-309 | NW | 20.5 | 726.41 (EOH) | 703.87 | 0.211 | 0.013 | 23 | 24 |

| DDH21-312 | NW | 0.99 | 570.09 (EOH) | 569.1 | 0.23 | 0.012 | 20 | 22 |

| Including | 216 | 360 | 144 | 0.26 | 0.014 | 39 | 40 | |

| DDH21-315 | HT | 284 | 465.43 (EOH) | 181.43 | 0.197 | 0.012 | 24 | 26 |

| DDH21-317 | HT | 5.18 | 331.82 (EOH) | 326.64 | 0.211 | 0.013 | 19 | 15 |

| Including | 184 | 264 | 80 | 0.255 | 0.014 | 28 | 24 | |

| DDH21-318 | HT | 7.87 | 370.94 (EOH) | 363.07 | 0.116 | 0.009 | 13 | 11 |

| DDH21-320 | HT | 16 | 401.42 (EOH) | 385.42 | 0.173 | 0.01 | 18 | 17 |

| DDH21-321 | HT | 132 | 511.15 (EOH) | 379.15 | 0.151 | 0.01 | 10 | 10 |

1NW: Northwest zone; HT: Horsetrail zone; EOH: end of hole

Geotechnical Drilling Program

The geotechnical drilling program was conducted with one skid-mounted drill rig in the Horsetrail and Northwest zones. Although these drill holes provide valuable additional geological and resource modeling information, their primary purpose was to investigate the geotechnical characteristics of the proposed pit wall areas with oriented core and optical televiewer, and to conduct hydraulic conductivity packer tests and install vibrating wire piezometers to guide engineering design. Where ultramafic rocks were intersected drill core samples from this program were one-half HQ core.

Table 2: Drill intercepts from the geotechnical drilling program2:

| Hole | Zone | From | To | Interval | Ni | Co | Pd | Pt |

| (m) | (m) | (m) | (%) | (%) | (ppb) | (ppb) | ||

| DDH21-310 | NW | 3 | 400.53 (EOH) | 397.53 | 0.218 | 0.012 | 18 | 22 |

| Including | 76 | 144 | 68 | 0.265 | 0.013 | 9 | 11 | |

| DDH21-311 | NW | 4.34 | 300.00 (EOH) | 295.66 | 0.204 | 0.01 | 6 | 8 |

| DDH21-313 | HT | 44 | 398.89 (EOH) | 354.89 | 0.173 | 0.013 | 6 | 7 |

| DDH21-314 | NW | No significant intervals | ||||||

| DDH21-316 | HT | 112 | 235.98 (EOH) | 123.98 | 0.147 | 0.012 | 18 | 13 |

| DDH21-319 | HT | 6 | 351.79 (EOH) | 345.79 | 0.244 | 0.015 | 31 | 26 |

| Including | 36 | 96 | 60 | 0.367 | 0.015 | 47 | 34 | |

2NW: Northwest zone; HT: Horsetrail zone; EOH: end of hole

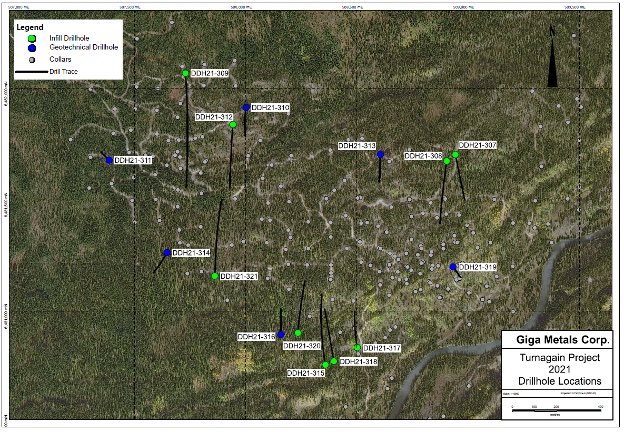

Figure 1: Infill and Geotechnical Drill Hole Locations in Horsetrail and Northwest zones

Seismic Refraction Survey

The seismic refraction survey was conducted by Frontier Geosciences from September 7, 2021 to October 6, 2021 in support of engineering design for the proposed Turnagain Mine tailings storage facility and had three main objectives: to estimate overburden thickness, to estimate overburden characteristics, and to estimate depth to water table. Information gathered will be used to select sites for sonic and diamond drilling to further characterize geotechnical characteristics for tailings storage design.

Quality Assurance, Quality Control

Diamond drilling in 2021 was conducted on the Turnagain property using both NQ and HQ diameter drill rods. Drills were oriented using a Reflex TN-14 Gyrocompass and, after completion of the drill hole, were surveyed using a Reflex EZ-Gyro. NQ core samples were ½ core collected using a hydraulic core splitter, while HQ core samples were ½ core collected with a diamond core saw. Giga Metals systematically inserted certified reference materials (standards) and blanks into each batch of samples at regular intervals. Samples were placed in sealed bags and shipped directly to SGS Canada Ltd.’s laboratory in Burnaby, British Columbia. Samples were prepared by crushing the entire sample to 75% passing 2 millimetres, riffle splitting of 250 grams and pulverizing the split to 85% passing 75 micrometres. The core samples also underwent a robust duplicate assay program that tests rejects and pulps for reproducibility. Approximately 10% of samples were also sent to a check lab, Saskatchewan Research Council Geoanalytics Laboratories (SRC) (previously TSL Labs). Base metal analyses were determined using the four-acid digestion method with ICP-AES finish. Precious metal analyses were determined with the fire assay method with ICP-AES finish. Analytical results are verified with the application of industry standard Quality Assurance and Quality Control (QA/QC) procedures.

Qualified Person

Greg Ross, P. Geo., a Qualified Person as defined by NI 43-101, has read and approved all technical and scientific information contained in this news release. Mr. Ross is the Company’s Turnagain Project Manager.

About Giga Metals’ Turnagain Nickel-Cobalt Project

The Turnagain Project hosts the Horsetrail nickel-cobalt deposit, a significant undeveloped nickel-cobalt sulphide deposit, located in British Columbia, Canada.

Engineering and metallurgical studies are underway with an objective of producing a Pre-Feasibility study. Extensive metallurgical work indicates a clean concentrate grading 18% nickel and 1% cobalt is reliably achievable using simple "off-the-shelf" processing technology. The Turnagain project covers a large, relatively underexplored land package prospective for additional ultramafic-hosted nickel-cobalt discoveries. Turnagain is one of the few projects in a stable jurisdiction that can potentially deliver large quantities of cobalt and nickel to meet the growing needs of the electric vehicle and energy storage markets at a time when many research analysts are projecting there will be shortages in the cobalt and nickel required by battery manufacturers.

On behalf of the Board of Directors,

“Mark Jarvis”

Mark Jarvis, CEO

GIGA METALS CORPORATION

Tel – 604 681 2300

Neither TSX Venture Exchange nor its Regulation Services Provider (as that term is defined in policies of the TSX Venture Exchange) accepts responsibility for the adequacy or accuracy of this release. No stock exchange, securities commission or other regulatory authority has approved the information contained herein.

Cautionary Note Regarding Forward-Looking Statements

This news release contains forward-looking information which is subject to a variety of risks and uncertainties and other factors that could cause actual events or results to differ from those projected in the forward-looking statements. Forward looking statements in this press release include the completion of a Pre-Feasibility Study.

These forward-looking statements are subject to a variety of risks and uncertainties and other factors that could cause actual events or results to differ materially from those projected in the forward-looking information. Risks that could change or prevent these statements from coming to fruition include changing operational costs for mining and processing; increased capital costs; the timing and content of upcoming work programs may be interrupted or delayed; geological interpretations based on drilling that may change with more detailed information; the availability of labour, equipment, infrastructure and markets for the products produced; and despite the current expected viability of the project, conditions changing such that the minerals on our property cannot be economically mined, or that the required permits to build and operate the envisaged mine cannot be obtained. The forward-looking information contained herein is given as of the date hereof and the Company assumes no responsibility to update or revise such information to reflect new events or circumstances, except as required by law.